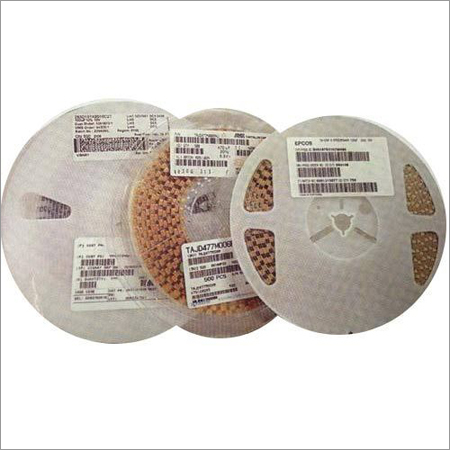

SMD Components

Price 50 INR/ Piece

MOQ : Packet Piece

SMD Components Specification

- IP Rating

- Not rated, depends on PCB assembly

- Sensors Specification

- Available as SMD sensors (temperature, pressure, etc.), specifics vary

- Operating Temperature

- -55C to +150C (varies by component)

- Usage

- Industrial

- Features

- Miniature size, high reliability, lead-free RoHS compatible

- Interface

- Solder pads for SMT placement

- Power Source

- External circuit supplied

- Output

- Dependent on SMD function (Signal, Power, etc.)

- Thermal Conductivity

- Ceramic body offers moderate to high thermal conductivity

- Response Time

- <1us for fast switching devices

- Components

- Resistors, capacitors, diodes, transistors, ICs, inductors

- Product Type

- Components

- Application

- Electronics

- Rated Voltage

- Dependent on SMD type (e.g., 25V, 50V, 100V possible for capacitors)

- Supply Voltage

- Volt (v)

- Size

- Any

- Dimension (L*W*H)

- Common codes: 0402 (1.0x0.5mm), 0603 (1.6x0.8mm), 0805 (2.0x1.25mm), 1206 (3.2x1.6mm)

- Function

- Surface Mount Device passive and active circuit integration

- Weight

- Ultra lightweight (typically 0.01g to 0.5g per component)

- Capacity

- Up to 100F for capacitors; Rated per part for other components

- Current Rating

- Up to several amps for some SMDs; varies by type

- Thickness

- Varying from 0.3mm up to 2.0mm depending on type

- Frequency

- High frequency capable; e.g., for ceramic capacitors up to several GHz

SMD Components Trade Information

- Payment Terms

- Telegraphic Transfer (T/T), Letter of Credit (L/C), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 500000 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

About SMD Components

Owing to our enriched industrial experiences, we are committed to offering a large variety of excellent quality SMD Components. These components include transistors, resistors, integrated circuits, microcontroller, and capacitors. The technology utilized by our diligent engineers to design the SMD components is surface mount technology. All the components have diverse uses which allow the client to operate the device in which SMD has been installed. We believe in providing a quality SMD components to our patrons to ensure their ease of operation and satisfaction.

Versatile Surface Mount Options

Our SMD components feature various termination typesincluding tin, silver, and goldproviding optimal solderability and long-term reliability in diverse circuit assemblies. Their miniature dimensions support compact electronic designs while catering to demanding industrial and consumer applications.

Robust Compliance and Reliability

Engineered to meet RoHS, REACH, and Halogen Free standards, most SMD components achieve UL 94-V0 flame ratings for enhanced safety. Moisture Sensitivity Levels (MSL) range from 1 to 3, ensuring suitability for reflow soldering processes with peak temperatures of 235C to 260C as per JEDEC J-STD-020.

Comprehensive Device Range and Applications

Choose from resistors, capacitors, diodes, transistors, ICs, inductors, and sensors, each designed for specific voltage, frequency, and current ratings. Their robust designs facilitate use in signal, power, and sensor circuits, making them integral to everything from consumer devices to complex industrial systems.

FAQs of SMD Components:

Q: How are these SMD components typically mounted onto circuit boards?

A: SMD components are mounted using surface mount technology (SMT), applied to solder pads on PCBs via automated placement machines. The soldering is completed through reflow processes, compatible with standard JEDEC profiles.Q: What are the main benefits of using tin-plated, silver-plated, or gold-plated end caps?

A: These termination types ensure excellent solderability, corrosion resistance, and electrical conductivity, enhancing long-term performance and reliability in PCB assemblies.Q: When should I select different tolerance levels for SMD resistors or capacitors?

A: Tolerance choice depends on circuit precision requirements: 0.1% is optimal for high-accuracy applications, while 10% can suffice for general-purpose or less critical circuits.Q: Where can I source these SMD components in India?

A: You can procure these components through authorized dealers, distributors, exporters, retailers, suppliers, traders, or wholesalers across India, specializing in electronic parts supply.Q: What process should be followed for safe soldering of SMD parts?

A: Use a reflow soldering process with controlled peak temperature (235C260C), matching the JEDEC J-STD-020 profile, and handle components according to their Moisture Sensitivity Level (MSL) guidelines.Q: How do the compliance certifications benefit my products?

A: RoHS, REACH, and Halogen Free compliance ensure your products meet stringent international environmental and safety standards, necessary for global market access and sustainable manufacturing.Q: What are the recommended usage scenarios for these SMD devices?

A: These components suit a broad range of electronics, including industrial machinery, consumer gadgets, automotive systems, and instrumentation, providing high reliability and compact size for diverse applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

ELECTROLOGICS DEVICES

GST : 24AKIPR0710Q1ZX

GST : 24AKIPR0710Q1ZX

Shop No. G - 1&2, Shantinath Estate, Gr. Floor, Shaikh no Pado, Opp. Zaveriwad, Relief Road,Ahmedabad - 380001, Gujarat, India

Phone :08045802321

|

ELECTROLOGICS DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry