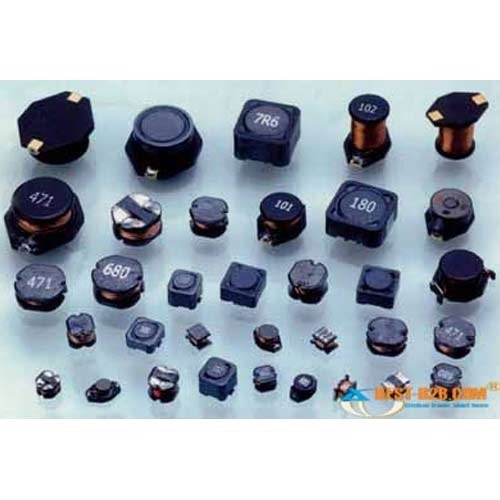

SMD power inductor

Price 10 INR/ Piece

MOQ : 500 Pieces

SMD power inductor Specification

- Components

- Ferrite core, copper wire, magnetic shielding

- Input

- DC input

- Power Source

- DC

- Interface

- Surface mount

- Operating Temperature

- -40C to +105C

- Features

- Low profile, high current, magnetic shielding, excellent solderability

- Output

- Stable DC output

- IP Rating

- IP20

- Usage

- Switching power supplies, mobile devices, LCD TVs, computers, and communication equipment

- Power Supply

- DC

- Product Type

- SMD Power Inductor

- Application

- Power Management, RF Circuits, Noise Suppression

- Rated Voltage

- Up to 30V

- Supply Voltage

- Up to 30V

- Size

- 5.0mm x 5.0mm

- Dimension (L*W*H)

- 5.0mm x 5.0mm x 2.0mm

- Function

- High-frequency energy storage and filtering in DC-DC converters

- Color

- Black

- Weight

- Approx. 0.3g

- Capacity

- Inductance 1.0H to 220H

- Current Rating

- 0.2A ~ 8A

- Thickness

- 2.0mm

- Frequency

- 1kHz to 1MHz

- Reliability

- Stable performance under vibration

- Package Type

- Tape & Reel

- Q Value

- High

- Maximum DC Resistance

- 4m ~ 600m

- RoHS Compliance

- Yes

- Cost Effectiveness

- Suitable for mass production

- Mounting Type

- Surface Mount Device (SMD)

- Inductance Tolerance

- 20%

- Test Condition

- 100kHz, 0.1Vrms

- Material

- Ferrite

- Shielding Type

- Magnetically shielded

- Max height

- 2.0mm

- Self-Resonant Frequency

- Up to 120MHz

SMD power inductor Trade Information

- Minimum Order Quantity

- 500 Pieces

- Payment Terms

- Cash on Delivery (COD), Letter of Credit (L/C), Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

About SMD power inductor

An inductor, also called a coil, choke, or reactor, is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a coil.Optimized for Modern Electronics

Designed for switching power supplies and energy storage, this SMD inductor offers a blend of compactness and efficiency. Its high Q value and magnetic shielding reduce noise and signal losses, making it suited for sensitive circuits in mobile devices, LCD TVs, and high-frequency power supplies. The low profile form factor accommodates dense PCB layouts, ensuring versatility in contemporary electronic designs.

Reliable Performance Under Demanding Conditions

Engineered with a ferrite core and built for surface mount, this power inductor delivers stable operation at temperatures from -40C to +105C and maintains electrical integrity during vibration. Its compliant package and process-friendly design support automated soldering, ensuring consistent quality in mass production environments across various industries.

FAQs of SMD power inductor:

Q: How does the magnetic shielding benefit the SMD power inductors performance?

A: The magnetic shielding effectively minimizes electromagnetic interference (EMI), protecting nearby sensitive components and reducing signal loss. This ensures the inductor performs reliably in noise-sensitive circuits, making it ideal for power management, RF, and communication applications.Q: What are the typical usage scenarios for this power inductor?

A: This inductor is widely used in switching power supplies, mobile devices, LCD TVs, computers, and communication equipment, where it serves critical roles in high-frequency energy storage, noise filtering, and DC-DC converter circuits.Q: When should I select a power inductor with a 20% inductance tolerance?

A: A 20% inductance tolerance is suitable for most power management and filtering applications where precise tuning is less critical, yet consistent energy storage and filtering are necessary. It is particularly cost-effective for mass production where small variations are acceptable.Q: Where should this SMD inductor be mounted on PCB designs?

A: Designed for surface mount technology (SMT), this inductor should be placed on the PCBs designated SMD pads during automated assembly, ensuring efficient soldering and integration within high-density or portable electronics layouts.Q: What is the process for testing the self-resonant frequency of this inductor?

A: The self-resonant frequency is verified under the specified test condition of 100kHz and 0.1Vrms. Reliable test equipment can measure resonance by gradually increasing the frequency until the inductance sharply decreases, indicating resonance.Q: How does the product benefit large-scale manufacturers or distributors in India?

A: Offering high reliability, RoHS compliance, and efficient tape & reel packaging, this SMD inductor supports automated assembly and shipping, making it highly suitable for dealers, distributors, wholesalers, and large-scale manufacturers across Indias electronic component market.Q: What advantages do the construction materials provide for the inductors operation?

A: The ferrite core delivers excellent energy storage and low core losses at high frequencies, while copper wire maintains low resistance for high-current handling. Combined with robust magnetic shielding, these materials ensure stable, efficient performance in demanding applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

ELECTROLOGICS DEVICES

GST : 24AKIPR0710Q1ZX

GST : 24AKIPR0710Q1ZX

Shop No. G- 1&2, Shantinath Estate, Gr. Floor,

Shaikh No Pado, Opp. Zaveriwad,Ahmedabad - 380001, Gujarat, India

Phone :08045802321

|

ELECTROLOGICS DEVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry